Market applications

Algafeed, Avespa’s first venture, is revolutionizing the aquaculture hatchery feed industry by enabling shellfish and shrimp farmers to thrive.

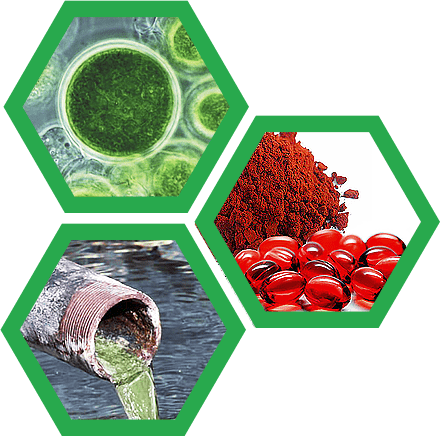

Avespa is also exploring applications of its technology in targeted sectors such as the production of natural molecules as well as leveraging the outstanding water scrubbing ability of microalgae to remove excess nutrients found in wastewater effluents.

Avespa’s role is to identify and develop technologies and processes that are tailored to the industry needs.

Avespa’s team has identified three primary areas of opportunities:

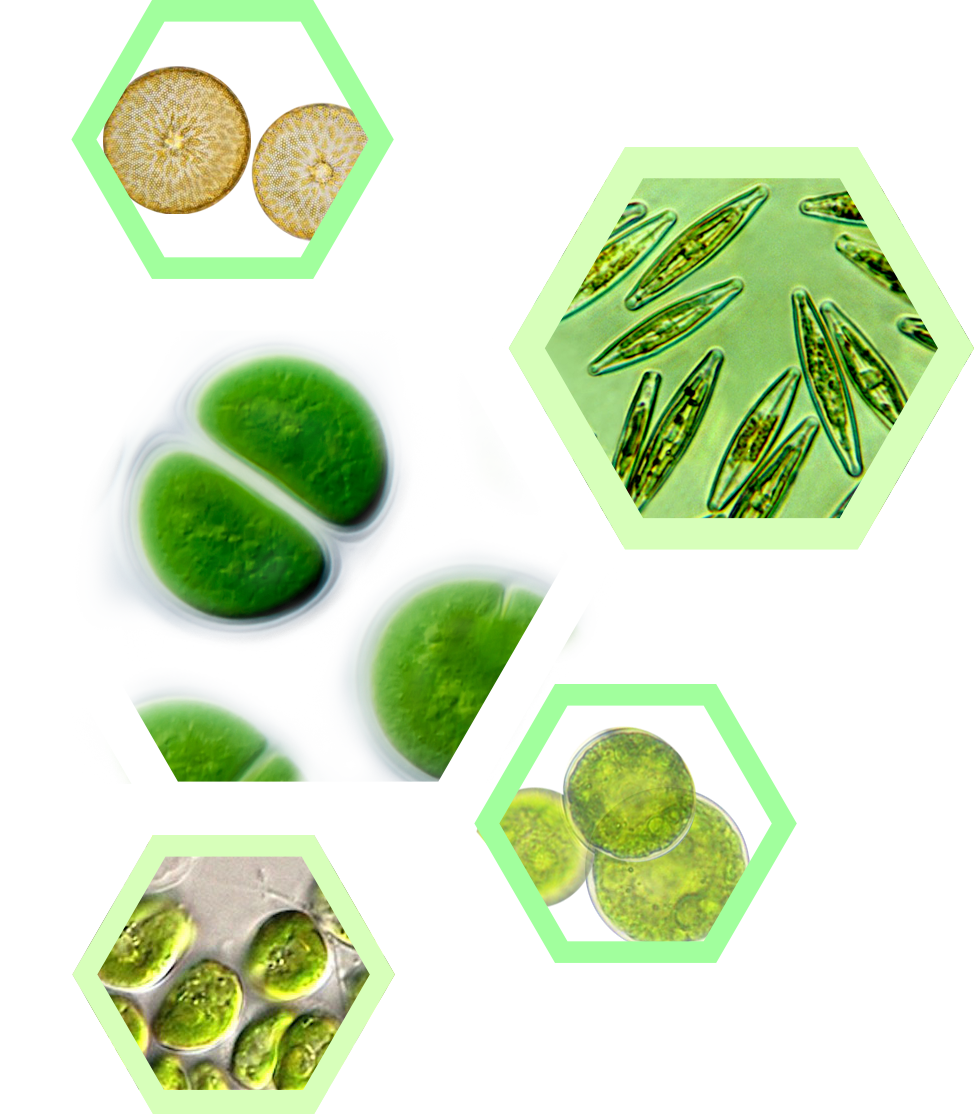

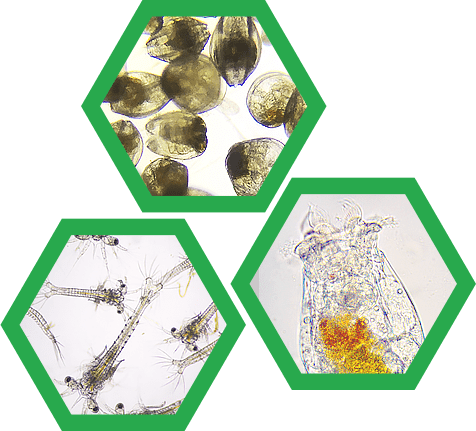

Aquaculture Live algal biomass is essential for the shrimp, shellfish and fish hatcheries

Algaceuticals Sustainable natural products for the pharmaceutical, cosmeceuticals and nutraceutical industries

Water remediation Industrial scale water scrubbing by providing a natural and effective solution for tertiary water treatment to remove a wide range of pollutant including, but not limited to, nitrate and phosphate

A Revolutionary Enabling Technology

A particular example with Algafeed is its impressive impact on Florida clam hatcheries. The live algae feed bottleneck is broken with high density tailored algal blends administrated with a daily feed chart, Algafeed enables clam farmers to:

- Condition their brood stocks for optimal spawn efficiency

- Reliably grow their larvae through set with high survival over 90%

- Expedite their whole process from spawn to raceway in less than 40 days

TIMELINE

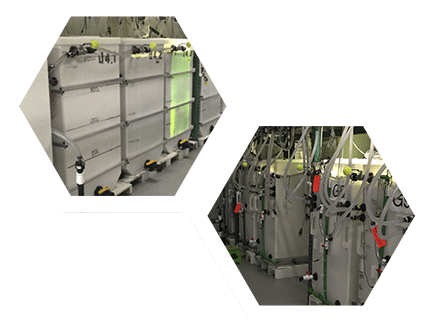

Technology Avespa has broken the barrier to produce any microalgae on a commercial scale using a patented modular scalable system. Using a holistic approach to develop an ultraefficient semi-continuous photo-bioreactor (PBR), we engineered a machine designed to industrialize photosynthesis leading to significant breakthroughs. Typically, Avespa’s technology is 10x to 50x more efficient than traditional PBRs.

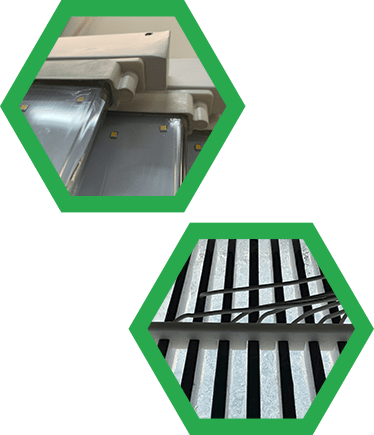

Light A fundamental breakthrough was to bring the light to the algae rather than the algae to the light. The optimal photon flux is delivered to every algal cell, Avespa’s technology is able to trigger photosynthesis in the most controlled and robust manner. Avespa developed proprietary immersible LED panels specifically designed for high density microalgae biomass growth.

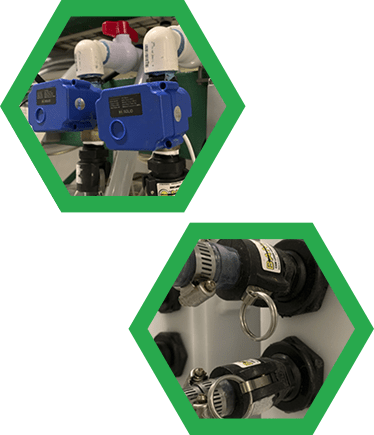

Water management & fluidics Water is a crucial component for microalgal biomass growth and long term maintenance. Using a totally enclosed fluidic system, ozone sterilized water (fresh or salt) can be delivered to each PBR tank with extreme precision and reliability. This firewall method avoids any external contamination with the immediate direct benefit of maintaining an ideal environment for continuous biomass growth.

Environment control Microalgae is a single cell organism that thrives in a controlled and regulated environment. Avespa prides itself with having no stress of any kind exerted on the microalgal biomass. Temperature, pH (acidity or alkalinity of a solution), air flow, light delivery, every key factor is delivered optimally and reliably day after day. Combined with online monitoring, all steps are taken to maintain the very best quality and health of the microalgae.

Nutrient optimization Avespa has optimized the ideal amount and delivery of macronutrients (nitrate, phosphate, silicate, and CO2) and micronutrients (heavy metals, minerals, and vitamins) in order to sustain exponential growth of microalgal biomass. This strict nutrient management allows any microalgae to grow on a perennial basis by conserving the utmost quality and freshness.

Operating practices and protocols Our patented technology requires optimized strict standard operating protocols (SOPs) in order to maintain maximal control. Troubleshooting guidelines, maintenance schedules, staff training have all been developed to simplify and optimize managing Avespa’s ultra-efficient PBR technology.

Constant (r)evolution and optimization Avespa is a company that prides itself on developing technology at the service of biology. By operating our Florida facility, we tightly focus on the user experience and overall process simplification. Growing microalgae is hard and unforgiving, Avespa’s team culture is driving forward, always aiming to improve and simplify PBR management enhancing reliability and system robustness. Avespa’s team abhors the status quo.

Downstream process integration Sourcing the microalgal biomass is fundamental step Avespa has cracked, however it is only the beginning. Avespa wants its biomass to be used with the utmost efficiency. Therefore our team always aims to address and develop best practices and management of the biomass it produces. For example, shellfish hatchery farmers are provided with the perfect algal blends and feed chart to get optimal results throughout their process.

Knowledge bank Avespa is at the nexus of many industries and therefore has a unique position. The Avespa team uses this wide spectrum of knowledge to the benefit of each and every client. Growing together and looking in the same direction is the most rewarding outcome our team can hope for.